Types of facade plasters - exterior thin-layer plasters

After applying on the facade thin-layer plasters can be barely recognized, regardless of a type. However, it is only a visual similarity.

Different plaster types

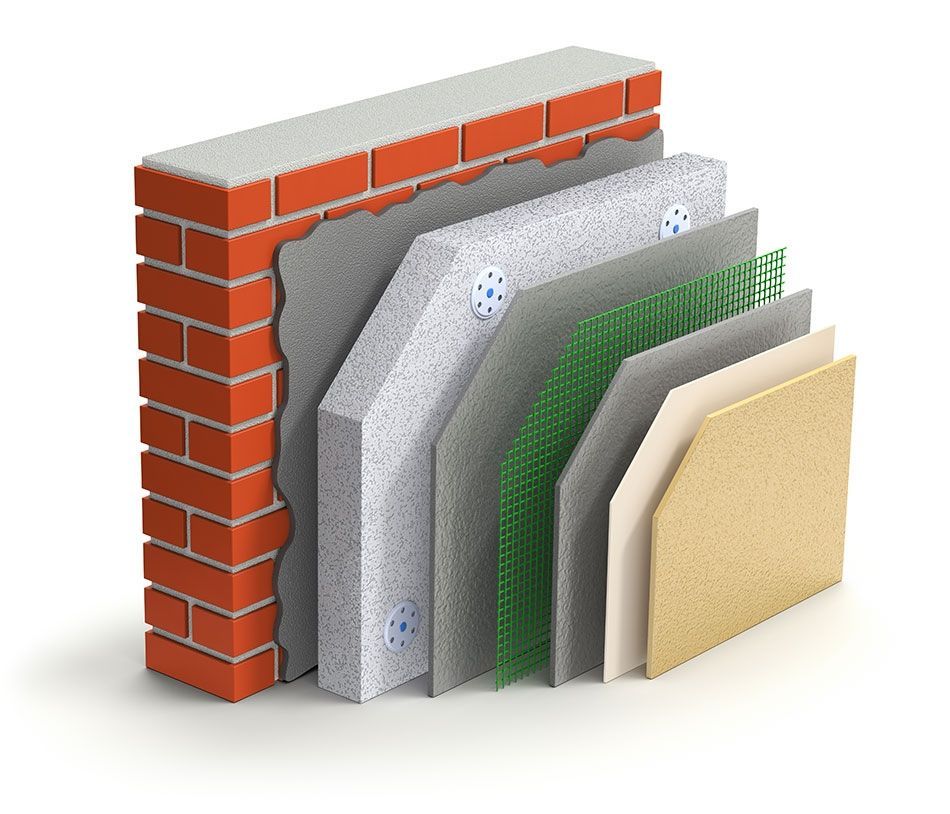

Thin-layer plasters have many different features. At the stage of selection and application we can immediately recognize their variability. Depending on vapour permeability degree, one can be used both on mineral wool and plaster, whereas the other only on polystyrene. They may require painting, or no coating at all (their application is the final stage of works). During its life they feature different resistance to dirt, algae and fungi. Therefore, a decision which one to pick, cannot be only based on the price and available colours.

The difference between plasters result mainly from binders used. However, we must remember that e.g. acrylic plaster of one manufacturer is not necessarily the same as similar product of the other manufacturer. Quantity and quality of binders varies, as well as pigments responsible for colours. In addition, they are modified with numerous additives. Nevertheless, each type of a thin-layer facade plaster has some characteristic features.

Plaster features

Mineral plasters contain cement and lime as binders, similarly to traditional thick-layer plasters. They feature high vapour permeability (low diffusion resistance), thus can be used both on polystyrene and mineral wool. They are alkaline, as a result they are resistant to algae and fungi. They do not feature electrostatic properties, hence they hold good resistance to dirt and dust. However, mineral plasters is painted the most frequently. Therefore, a paint type determines ultimately the resistance to dirt and biological hazards. Mineral plaster is available in grey version (to be painted), white (does not require painting), and possibly tinted version, but only in a limited palette of light and pastel colours. We need to emphasise here that painting is not only an extra cost of paint and labour. It is also necessary to ensure time for plaster curing. If we are thinking of applying an acrylic paint, i.e. featuring low vapour permeability, it’s necessary to wait at least 3 weeks, whereas in case of a silicate paint - 3-5 days.

For performance manner it’s also important that mineral plasters are in the form of powder to be mixed with water. Water must be clean and added in the quantity exactly defined by the manufacturer. Durability and adhesion of too diluted plaster is deteriorated and its structure is more porous.

Acrylic plaster is a product based on synthetic (acrylic) resins with various additives. The basic limitation to its use is low vapour permeability, which makes it unsuitable for mineral wool insulation. It features very good elasticity and resistance to mechanical damage. Due to the electrostatic properties and neutral pH, it is less resistant to dirt and are more susceptible to impact of algae and fungi. Therefore, it is subject to modification, e.g. by adding Teflon (FoveoTech TPT 40FoveoTech TPT 40 TPT 40 Polymer Render with Teflon® surface protectorSee more), which decreases susceptibility to dirt and facilitates washing. Acrylic plasters feature very low absorption and can be washed under pressure.

TPT 40 Polymer Render with Teflon® surface protectorSee more), which decreases susceptibility to dirt and facilitates washing. Acrylic plasters feature very low absorption and can be washed under pressure.

From an investor and contractor’s point of view it is important, that acrylic plasters they can be tinted and a colour palette is rich. There are 240 colours available in the FoveoTech system.

They are sold in buckets, in the form of paste consistency. Prior to its use, it must be mixed carefully.

Silicate plasters are made on the basis of potassium water glass with an addition of synthetic resins. They feature very high vapour permeability, thus can be applied for both polystyrene and mineral wool. They form a strong bond with the substrate made of adhesive, due to a chemical reaction between them. They are quite resistant to dirt and very resistant to biological corrosion i.e. algae and fungi. It primarily results from a strong alkaline reaction. Therefore, they particularly recommended for areas in the vicinity to forests and water reservoirs. They can be tinted and a colour palette is not as rich as in the case of acrylic products. They require quite high temperature during application - at least 10°C, but not more than 25°C, and air humidity to 80%. Low temperature extends the drying time and prevents the plaster with appropriate bonding with the substrate.

They are sold as ready-to-use compounds, which only must be mixed prior to use.

Silicone plasters are polymer products (based on synthetic resins), similarly to acrylic plasters, however, they significantly vary from them. Above all, they are vapour permeable, which means they can be also used on mineral wool. They feature low absorption along with resistance to dirt settling. Consequently, they hold so called self-cleaning properties - in areas exposed to rain, water washes away the dirt. Certainly, we cannot expect this effect in areas where rain can barely reach, e.g. under a wide roof eaves. However, cleaning the facade in the said areas won’t be a difficult task. During the production stage fungicidal agents are added, which ensure a high resistance to biological corrosion. They are available in numerous colours, just like acrylic ones. They are purchased as a ready-to-use plaster compound in buckets.

Thus, they are universal products holding very good parameters. However, they are the most expensive of all thin-layer plasters.

Silicate-silicone plasters combine the features of the both products, but they are less expensive than silicone ones.

Mosaic plasters contain acrylic resins as binders, and coloured coarse aggregate. Visible coloured aggregate provide a decorative effect, ensure a high resistance to mechanical damage and allow to wash and scrub the plaster without a risk of damage. Also, they contain additives preventing fungi from development. As a result of the said features, they are frequently used to finish plinths and ornament areas around window, grooves and cornices. They are often used indoors, in areas exposed to damages and dirt, e.g. staircases. They are available in several dozen colours.