The most frequent errors made when insulating a home

We could write numerous books on errors made when insulating a house. Here we would like to present the first “portion” of commonly made errors, which practically cannot be corrected.

Inappropriate system

Why does a manufacturer offer a few thermal insulation systems? It is because each one is adjusted to particular conditions. First of all, different materials are required when using mineral wool and different ones in case of polystyrene. Yet parameters of all the wall layers are important, therefore we cannot mix systems and pick materials randomly. There is no point in applying a vapour permeable plaster (e.g. mineral), if later we apply an acrylic paint with low vapour permeability on the facade.

All doubts, regarding whether a particular system will be suitable for us, should be discussed with the manufacturer’s technical expert. In particular, it refers to insulation of existing houses. In their case a situation sometimes might be non-standard, e.g. insulation of three-layer walls or a house in the vicinity to the forest. Then, the room for manoeuvre as far as selection of materials is concerned, is very limited and only someone who is knowledgeable, can assess which solution will be the right one. Another example is when someone buys an objectively good product but not accommodated to our needs.

Incorrect substrate preparation

Walls must be even and provide good adhesion and bearing capacity. Otherwise, it is impossible to install firmly thermal insulation boards (sheets), and plaster start cracking then. In extreme cases, the boards themselves can fall off. Protruding unevenness in the form of dry adhesive must be removed. All the grooves must be filled with adhesive prior to installation of the boards. Substrate irregularities cannot exceed 2cm. Otherwise the difference in adhesive thickness will be too big and during bonding it might shrink in various degree and consequently twist the boards.

When insulting an existing building it’s necessary to test bearing capacity of the plaster - thud occurring during testing can indicate that the plaster is no longer fixed to the substrate and needs to be removed. Plaster can also feature poor quality. It’s recommended to carry out an adhesion test of the new insulation. To do it, it’s necessary to fix a few polystyrene blocks of 10x10cm dimensions to the most suspicious areas. After min. 2 days, when the adhesive has cured, remove the blocks. Polystyrene should be torn. If plaster also comes off, it indicates that the old plaster should be also removed, as it won’t provide enough bearing capacity.

Surfaces of new and rough walls should be primed. The primer levels the substrate absorption and bonds tiny particles with the substrate, enhancing adhesion.

Faulty installation

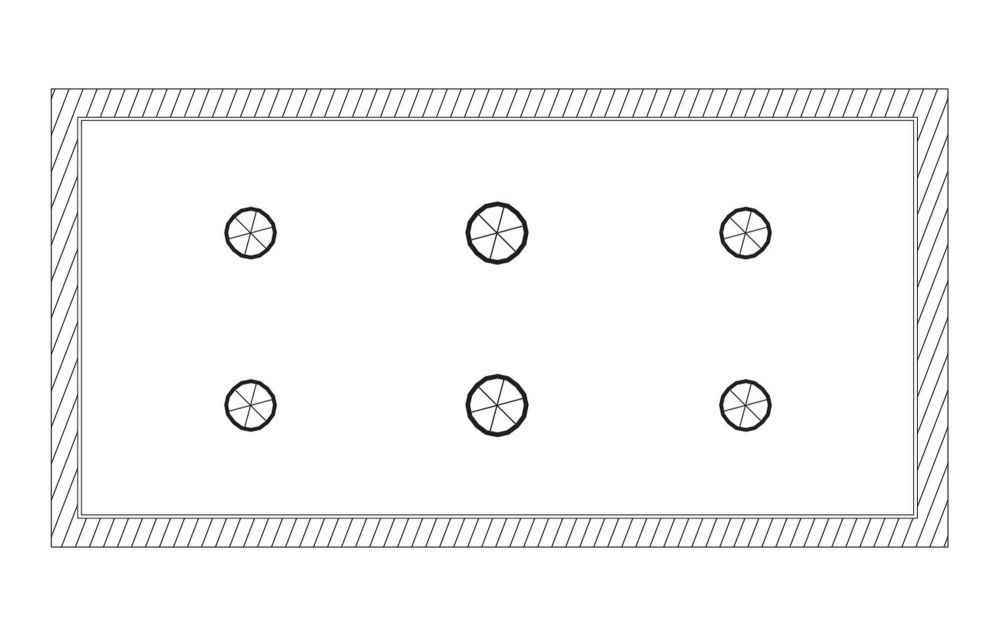

Correctly applied adhesive onto a board of polystyrene or mineral wool is min. a 5 cm stripe around its surface (edges) and at least 6 mounds in the middle, in total at least 60% of the board’s surface. A lack of adhesive around the entire board (edges) may result in formation of gaps. In addition, its edges cannot have a solid foundation. When we fail to provide the mounds in the middle of the board, it has no foundation and adhesion.

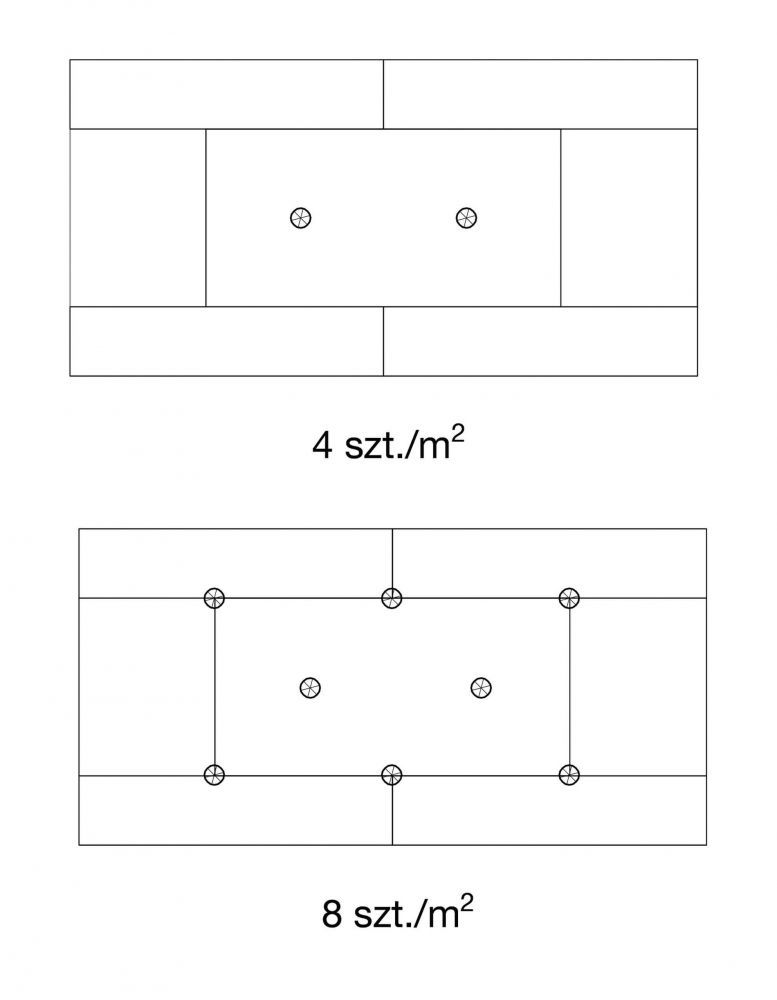

Anchoring is not also free from defects. First of all, anchors must be of relevant length, adjusted to the wall material and the insulation. For example, mineral wool, as it is a lot heavier and therefore is installed with steel anchors, not plastic ones. It is assumed that an anchor should be at least 5 cm longer than the insulation thickness. A typical distribution of anchors is the following: 4 items/m2 (2 per board) in the middle section of the wall and at least 6 items/m2 close to edges and around windows and doors, as the risk of board’s coming off is the biggest in these areas. Attention! Anchoring is carried out min. 2 days after installing the boards, when the adhesive is cured.