How to prevent thermal bridges while insulating a building?

From homes, heat escapes not only through uninsulated walls or e.g. leaky windows but also through thermal bridges. How to prevent them?

Thermal bridges stand for an area where heat escapes in large and uncontrolled quantity. This can reach as much as 20-30%, and will always be proportional to the size of of the thermal bridge. They contribute to dampened walls, algae and fungi development, and sometimes serious damages to construction elements of the building. The reason for that is, that in the area of a thermal bridge, the temperature of the wall surface often drops below the dew point.

Then, how to prevent thermal bridges while insulating a house? In practice the complex question consists of the other two: how to install polystyrene sheets, and how to fill in the gaps between them?

How to install polystyrene sheets?

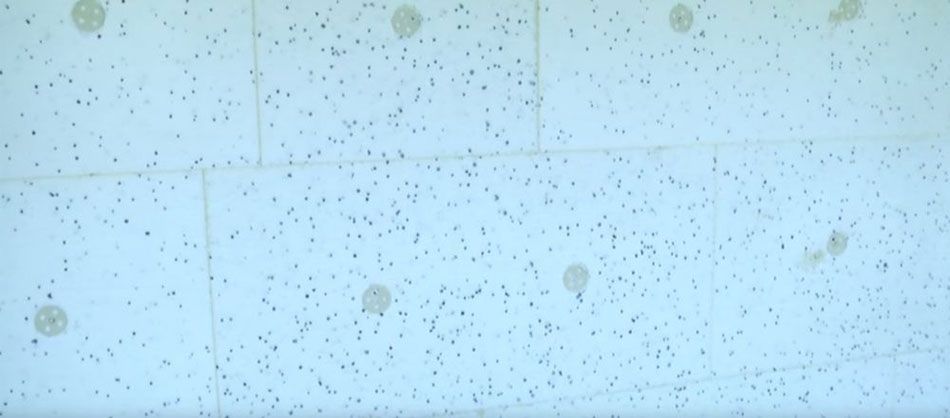

In a horizontal arrangement, applying an alternate system of vertical joints (alternation should be at least 15 cm). It’s best to use complete and undamaged sheets. Those cracked, e.g. can be used later - while insulating unusual areas - including wall corners which going down at an angle different than 90 degrees, or polygon bays.

It’s necessary to cut the sheets so that horizontal and vertical joints do not coincide with the edges of the holes.

The purpose of this application is to prevent the adhesive from going out of the sheet’s edges. Otherwise, it won’t be possible to put them together. Excessive adhesive must be removed - the sooner, the better. The thickness of the adhesive layer after pressing the sheet to the substrate cannot exceed 10 mm.

How and what to use to fill in gaps?

In the event of larger gaps than 2 mm, it’s necessary to use polystyrene strips or high expansion polyurethane foam. Remember to remove its excess after drying (use a sharp knife), and next abrade the surface with coarse paper or abrasive float and remove dust with a vacuum cleaner. The reason for that is to provide a smooth surface after installing the sheets and ensure the same insulation in every area.

Under no condition are we allowed to fill in the gaps with the adhesive for polystyrene since then thermal bridges phenomena is guaranteed! Similarly to not precisely installed sheets.